Southern Indiana Business Report

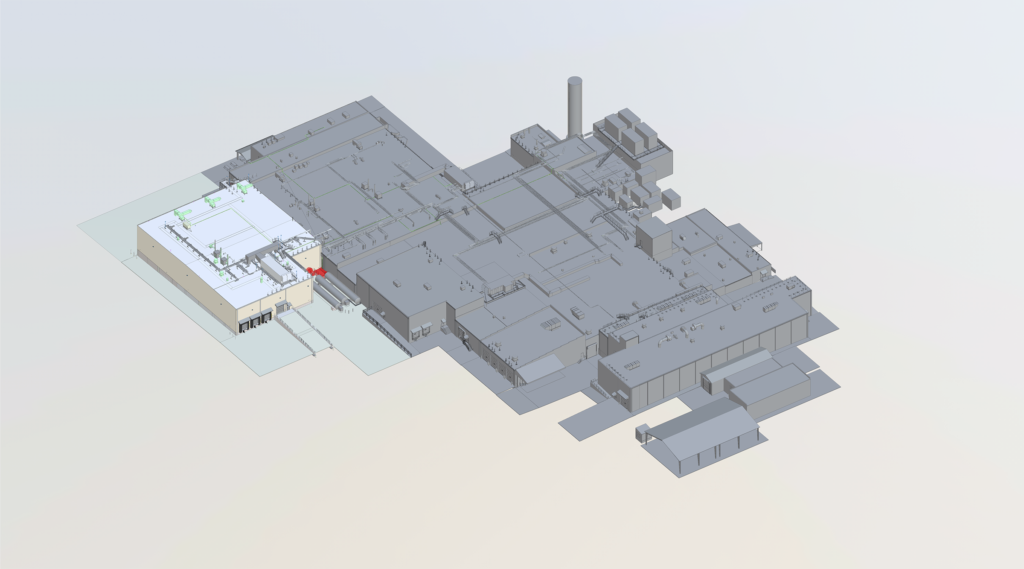

HUNTINGBURG — Work has begun in Huntingburg on a $12.8 million expansion for Farbest Foods Inc., a global supplier of raw, fresh and frozen turkey products. This project will expand the deboning room at the plant, enabling Farbest to streamline its deboning process and improve output.

“It’s important for us to keep evolving and improving our practices at Farbest so we can maintain our mission of providing customers with top-grade turkey products,” said Ted Seger, president of Farbest Foods.

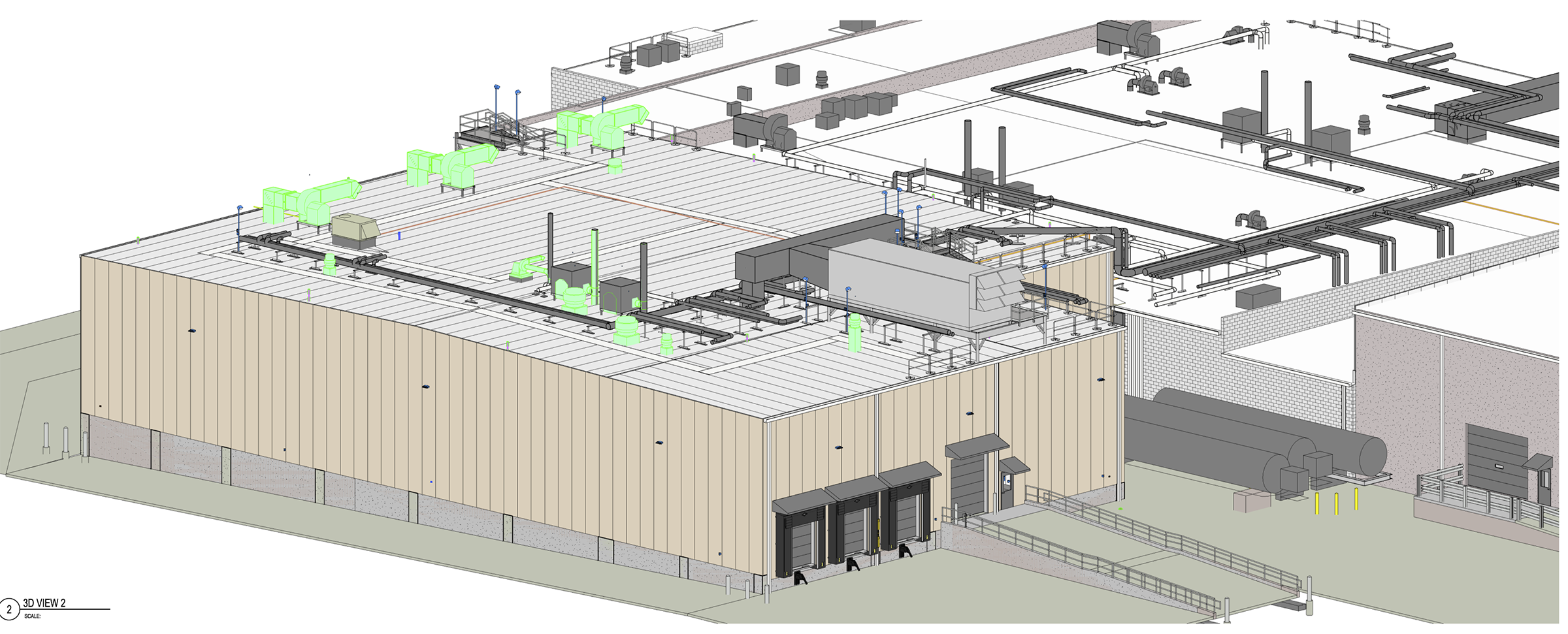

Stellar, a fully integrated design, engineering, construction and mechanical services firm, is providing planning, design, pre-construction and construction services for the more than 22,000-square-foot expansion. The company was established in Jacksonville, Florida, in 1985.

“We knew Stellar’s expertise and experience would make them a great partner as we work to improve our already world-class facility,” Seger commented.

The project is on track to be completed in July.

“This new addition will enable Farbest to transition from manual turkey deboning to a more automated, machine-driven process,” said Tyler Netting, the project’s lead construction manager with Stellar. “We’re building out the new refrigerated space and adjacent shipping docks, which will enable the owner to incorporate new equipment into the deboning room.”

First built in 1969 and expanded in 1986 and again in 2008, the Farbest facility has presented unique challenges for the Stellar team. Stellar assured Farbest of a successful build after identifying soil issues and deciding on how to match new construction technology with an existing 35-year-old structure.

After considering various possibilities, Stellar’s project management team selected a solution involving fill and wick drains under the expansion site, which are designed to speed up the settlement process and reduce the risk of long-term settlement issues.

“There are other solutions we could have pursued, but we decided on an approach that was optimal for the site and the owner’s objectives,” said Michael Grochowski, Stellar’s lead design manager on the project. “This method was both effective and cost-efficient. It also speaks to our team’s expertise and willingness to investigate creative solutions to best meet our clients’ goals on any project.”

The turkey deboning room expansion is Stellar’s second and largest project with Farbest. The family-owned Jasper-based supplier of raw, fresh and frozen turkey products to top-brand value-added further processors across the United States and globally. Its total live production surpasses 600 million live pounds annually, and up to two million pounds per day of raw, fresh and frozen turkey meat is shipped out daily from the firm’s distribution centers. Farbest’s two milling operations, known as JFS Milling Inc., supply contract growers and feeder hubs.