Carol Johnson, Southern Indiana Business Report

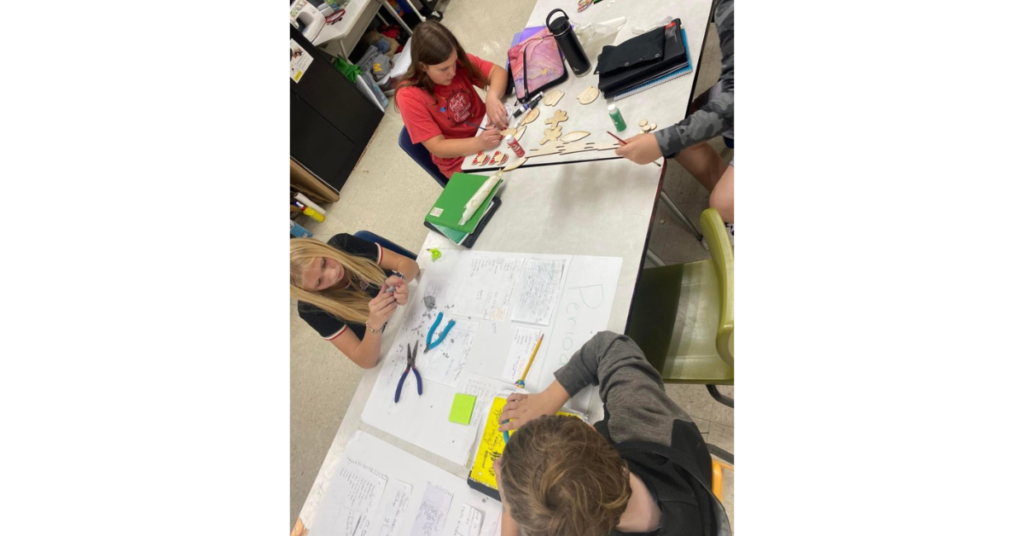

MITCHELL – Orleans High School junior Julia Isom stood at a lab table in the Dawgs Den working on a crop rotation demonstration project for Future Farmers of America.

She cut different crop boxes using the Glowforge in the lab and then used wood glue to put them together. She then pointed out small corn, soybeans, and wheat pieces she made using a 3D pen, which is similar to a hot glue gun.

Not so long ago, Isom didn’t feel confident working in her school’s fabrication lab.

“I have always been super scared of new technology because it can be frightening for kids who did not grow up around it, so this opened my eyes being like, ‘Wow, it doesn’t have to be scary when you have a really nice professional who has trained you to do all of this,’” she said.

The Dawgs Den is the digital fabrication lab at Orleans Junior-Senior High School. The Dawgs Den, along with the Novus Lab at Mitchell Junior High School and the Rock at Shoals Elementary School, are providing new learning opportunities for students.

Digital fabrication labs are unique learning environments where students have access to a variety of tools and technology to explore the engineering design process, coding, and programming integrated with academic content. This learning environment provides students with modern workforce skills to succeed in their future careers.

The labs contain physical computing devices, 3D printing machines, laser cutters, CNC routers and vinyl cutters.

The three schools belong to the Collaboration of Shoals, Mitchell and Orleans Schools. In 2020, Apryl Kidd, COSMOS director, was part of a Regional Opportunity Initiatives group of educators that visited a digital fabrication lab at a K-12 school in Chattanooga, Tennessee.

Future problem-solvers

Since 2019, nine labs have launched at schools in the 11-county Indiana Uplands region. In the Uplands Fab Lab Network, teachers and students alike are learning that the limits are endless for those eager to learn new technology and use the fabrication equipment available right at their fingertips.

The goal is for students to walk away as adaptive problem solvers passionate about experiential learning, prototyping, creativity, and problem-solving.https://regionalopportunityinc.org/2023/01/28/everyone-is-a-maker/

Kidd said the labs are starting to impact school culture.

“We’re starting to see interest grow and students are making connections to their academic learning,” Kidd said.

The labs are staffed with lab leads who guide the process for students and aid teachers as they integrate work in the labs with their lesson plans.

Students have made award medals, ornaments and items the school, in the past, would have purchased from an outside vendor.

Kidd said a biology class at Orleans was studying cells and created a visual model of a cell in the Dawgs Den.

“Another thing we’re seeing is choice, students have a choice in what they’re learning. Some are more drawn to 3D printing, others love to code. They have a choice in what they’re creating and how they’re creating.”

Apryl Kidd, COSMOS director

Alison Kern taught sixth-grade science for 10 years before moving into the Novus Lab at Mitchell Jr. High.

As the new lab lead and project-based learning coach, Kern started a system for students to become experts in the lab by passing safety quizzes and showing Kern what they know about specific tools in the lab, such as the Glowforge 3D laser cutter.

Students receive a badge, and their pictures are displayed in a common area signifying that they are certified to help others with those specific tools.

“I like that it lets kids have a choice in their learning and pursue areas in the lab they are passionate about,” Kern said of her experts. “I am not going to force them to become an expert in anything. I want them to love it.”

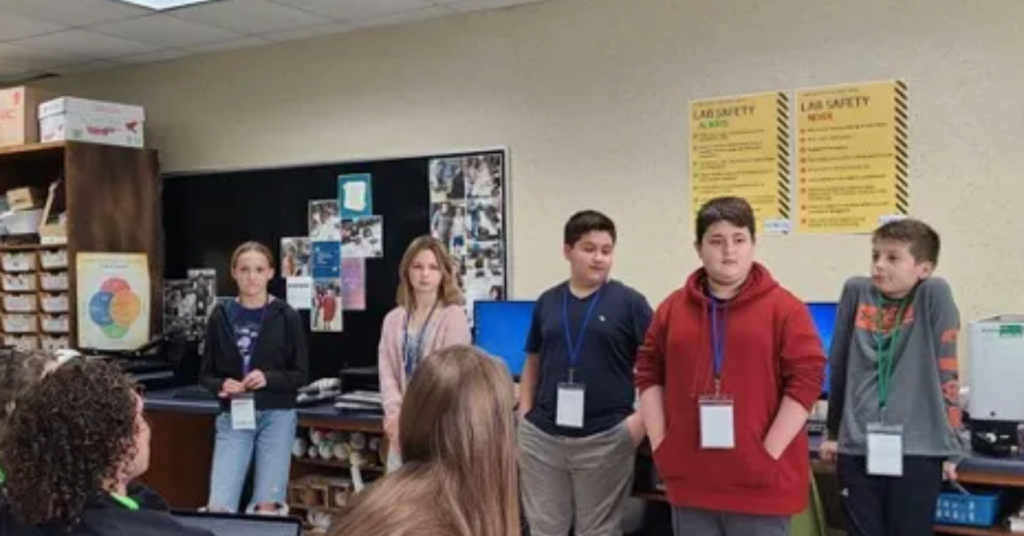

Kern invited five of her student experts to share more about their time in the lab. Students showcased their expertise in the Glowforge, handheld power tools, nonpower tools, and soldering.

Working in the lab gives the expert students more hands-on experience they believe will be valuable once they enter the real world, they explained, while also giving them another way to learn that is not sitting at a desk.

Selecting project materials and ensuring everything is cut and measured correctly are some of the challenges students have conquered in the lab so far – which only helps the learning process, explained ROI Education Specialist Emily Menkedick.

Each Mitchell Junior High student has visited the Novus Lab at least once this school year. This allows Kern to show students and teachers what is possible in the lab.

“If a kid can think it, we can do it,” Kern said.

Creating digital fabrication labs were part of COSMOS’ application for Ready Schools funding. COSMOS received $90,000, which were divided among the three schools to purchase equipment. Each school also has a full-time lab lead.

In Shoals, the Rock is connecting with the community. Students made ornaments for the Martin County Alliance for Economic Growth to include in site selector gift bags.

Inspiring big dreams

In November, the Uplands Fab Lab Network met to check out the Novus Lab and the Dawgs Den.

Teachers observed the labs in action and got to see how these small-town fab labs are inspiring big dreams. Mitchell has a population of less than 5,000 people, while Orleans has a little more than 2,000 residents.

Jeri Brown is lab lead in the Dawgs Den.

Her lab intern, senior Emily Dewitt, has earned 10 badges in an expert system similar to Kern’s in the Novus Lab.

Dewitt plans to be a nurse practitioner in a NICU. She is in the Dawgs Den twice a day, learning what she can from Brown and supporting other students. The Dawgs Den first opened its doors her sophomore year, but this is the first year she has been in the lab every day.

“I am lucky enough that Mrs. Brown has taught me how to use almost everything here, so that will help me with a lot of life skills,” she said.

“If I want to renovate my own house, I can use my own power tools. I can just do it myself. I think it’s cool she has been able to teach me all of this.”

“Be creators – not just consumers” is written on the chalkboard behind Brown as she explains how the Dawgs Den operates to her fellow lab leads.

She said she tries to involve the entire school community with different schoolwide activities – hoping to bring all seventh through 12th-grade students into the lab. Brown creates monthly design challenges, and the student with the winning design gets to come into the lab to make it a reality.

“I think I have been very student-focused, focusing on badges and credentials, getting the students in here so I can teach them,” she said.

As the students gain proficiency in their school’s fab labs, they are developing skills needed in the Indiana Uplands key industry sectors: advanced manufacturing, life sciences, and national security and defense.

“A mindset towards iterating, creating, and collaborating are all of the things that our employers are saying they need and that we (ROI) know will be the difference between good and great,” Menkedick said.

Suzannah Couch, storytelling specialist at Regional Opportunity Initiatives, contributed information to this article.